An SEB R&D team member explaining the refuelling of hydrogen at the station.

HYDROGEN produced can come from natural gas that generates carbon dioxide, but this is not the case at Southeast Asia’s first Hydrogen Production Plant and Refueling Station.

The facility at Bintawa in Kuching uses water to produce carbon-free hydrogen.

Hydrogen is the simplest and lightest element. It’s not only 14 times lighter than air but also odourless, colourless and tasteless.

Named after the Greek words ‘hydro’ for water and ‘genes’ for forming, hydrogen makes up more than 90 per cent of all of the atoms, equalling 75 per cent of the mass of the universe.

Hydrogen is seen as the most promising alternative energy carrier, opening up sustainable mobility choices in everyday life.

Two electrolysers are used to produce hydrogen gas.

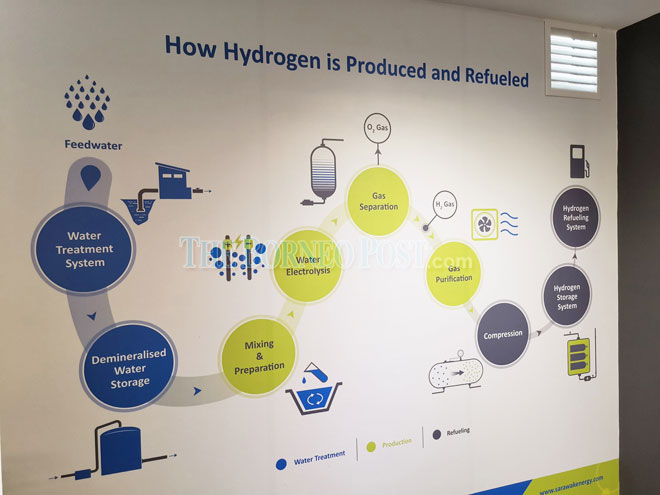

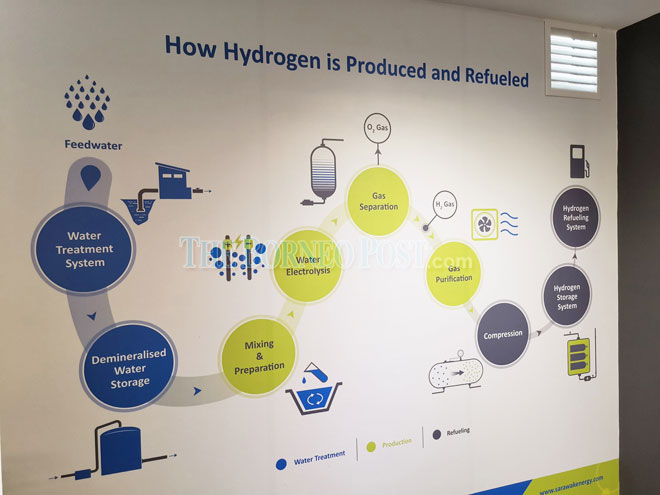

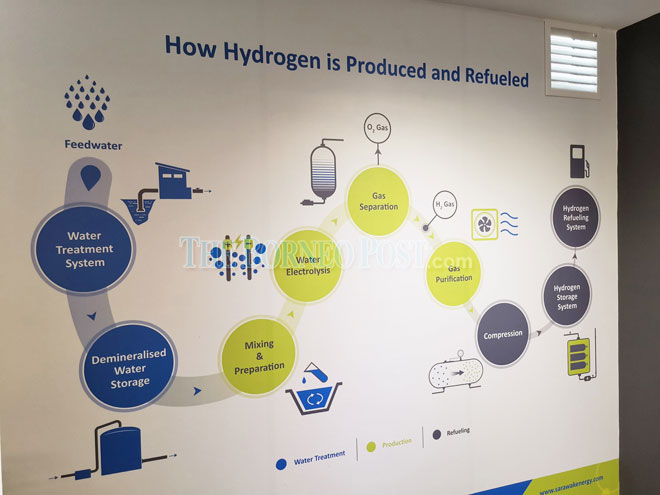

In Sarawak, the integrated facility consists of a plant that produces hydrogen through an electro-chemical process called electrolysis and a refuelling station for hydrogen-powered vehicles.

The plant is capable of producing up to 130 kg of hydrogen per day at a purity of 99.999 per cent. It comes with a full capacity of refuelling up to five and 10 hydrogen-powered buses and cars respectively per day.

The construction and operation of the integrated facility was undertaken by Sarawak Energy Berhad (SEB) in collaboration with Linde EOX Sdn Bhd, a subsidiary of global Linde Group and a leading industrial gas supplier in Malaysia. SEB is partnering with Linde which works at the forefront to move the world towards zero emissions.

Two compressors are stored in this modular container.

Linde is the technology leader for sustainable hydrogen solutions — from hydrogen production technology, supply competence, fuelling technology and equipment to applications and services.

It has been producing pure hydrogen to industrial users since 1910, besides having already engineered and constructed over 350 hydrogen production plants and is operating more than 110 of them.

It has also equipped more than 160 Hydrogen Fuelling Stations (HFS) around the globe, including over 10 bus depots.

Linde has built the world’s first HFS for passenger train in Lower Saxony, Germany.

Hydrogen is an odourless, colourless and tasteless gas that is produced through either natural gas steam reforming or the electrolysis of water.

Lighter than water, it burns with an invisible, clean (carbon-free and soot-free) flame.

It is the only fuel gas that does not contain any carbon atoms.

Powerful energy carrier

Hydrogen has the highest thermal conductivity of all gases, releasing zero harmful emissions when reacting with oxygen in a fuel cell.

It’s a powerful energy carrier, holding about three times more energy than petrol (based on weight).

An SEB R&D team member explaining the refuelling of hydrogen at the station.

Thanks to zero emssion, it’s environment-friendly and as far as Sarawak’s development plan is concerned, green initiative is a top priority.

The Integrated Hydrogen Production Plant and Refuelling Station is in line with Chief Minister Datuk Patinggi Abang Johari Tun Openg’s vision to establish an emission-free public transportation system.

Towards this end, the Sarawak government has entrusted SEB to spearhead energy-related research, starting with a feasibility study on hydrogen and fuel cell applications in Sarawak.

This year marks the first hydrogen-powered bus trial in the city. The project was announced in Nov 2017 followed a month later by the announcement of the first hydrogen mobility trial project for Kuching.

In May 2018, the project was awarded to Linde for implementation.

Abang Johari performed the ground-breaking in July 2018 alongside the signing of a Memorandum of Understanding (MoU) with Linde on a joint technical study on value chain technology.

In October 2018, SEB sealed an MoU with Shell MDS (M) Sdn Bhd on a joint assessment for low-cost hydrogen production technology via electrolysis.

In May this year, the Chief Minister launched the first Southeast Asia’s Integrated Hydrogen Production Plant and Refuelling Station.

At the facility, a restricted zone is set up at the back where two electrolysers and two ionic compressors are in place for producing hydrogen.

Inside one of the three SEDC hydrogen-powered buses.

There is also a system that treats feedwater for the electrolytic process. Once treated, the water is kept in demineralised water storage for the next stage — mixing and preparation.

After that comes the electrolysis of water, a process using electricity to break the bonds between the constituent elements of water, hydrogen and oxygen, and releasing them as gas.

Also called water-splitting, it requires, ideally, a potential difference of 1.23 volts to split water.

No negative impact

Hydrogen gas can be burned to produce power with no negative impact on the environment, unlike power produced by burning fossil fuels.

The hydrogen produced will go through a process called compression and later stored for refuelling.

“There’s no carbon dioxide at all when you do electrolysis,” said an SEB research and development (R&D) team member during a recent media familiarisation visit to the facility.

Most similar facilities are located in Europe and South Korea and Sarawakians should be proud to have a first-of-its-kind facility not just in Malaysia but also Southeast Asia.

Sarawak Energy Berhad is unable to reveal the cost of hydrogen production at the facility, constructed at a total cost of RM16 million.

The company presently regards the facility as a pilot project, focusing on R&D on hydrogen technology.

Recently, the Chief Minister announced plans to build six more such facilities across the state –two said to be in Kuching and one each in Sri Aman, Sibu, Bintulu and Miri.

Even though the production cost is not made known, SEB believes hydrogen will eventually be cheaper than fuel due to economies of scale with more countries adopting the technology.

Currently, the Sarawak Economic Development Corporation (SEDC) owns three hydrogen-powered buses while SEB has two hydrogen-powered cars — Hyundai Nexo.

On top of the two Nexos, SEB also has four electric cars and 24 electric scooters as part of its corporate fleet to demonstrate its commitment to greening the transportation sector in Sarawak.

Safety first

The Integrated Hydrogen Production Plant and Refuelling Station was designed and constructed according to relevant regulations, codes, standards and best practices referenced from the design and operation of other international world class facilities.

As such, the plant, including the refuelling station, is safe — and entry is not granted to any random person.

During the media familiarisation visit, journalists and photographers were required to surrender their MyKads or driving licences for a visitor’s pass.

Even with the visitor’s pass, they were not permitted to enter the restricted zone without wearing fire retardant clothes (FRC), jackets and pants, anti-static safety footwear, hard hats and safety eyewear.

A hydrogen bus on the road.

Electronic devices such as handphones and cameras are not allowed in the restricted zone.

The media team was taken to the refuelling station near the entrance to the facility. There are only two nozzles — one for buses and the other for cars.

According to the SEB R&D team, a hydrogen-powered car can travel 100 km on a kg of hydrogen. The same cannot be said of buses which depend on passenger load.

It is also learnt the two Nexos come with a maximum fuel tank capacity of 6.33 kg.

While most people are aware it takes much longer to recharge an electricity car, refuelling of a hydrogen-powered car requires only a couple of minutes.

On whether hydrogen technology poses any safety issues, SEB Strategy and Corporate Development executive vice president Ting Ching Zung said people should not worry about this.

A large safety warning sign at the restricted zone.

“The Chief Minister is using a hydrogen car. What’s more, a visit to Paris, led by him, found a hydrogen refuelling station near the Eiffel Tower.

“That the refuelling station is sited in the vicinity of a famous landmark in Paris shows how safe it is,” Ting noted.

For now, the production cost of hydrogen is not considered economy but this should change with time as more countries adopt the technology.

As far as Ting is concerned, SEB is playing its part to better prepare Sarawak for change in the future, and all the research done and carried out at the facility is part of it all.

The research focuses on how to operate and improve hydrogen technology and figure out how suitable the application is for Sarawak.

“Society is moving more to green energy,” Ting said, believing hydrogen economy will eventually lead the way to a greener environment.

An illustration at the gallery of the facility showing how hydrogen is produced and refuelled.